When it comes to fiber optic cables, keep in mind that choosing for incorrect types of cables may result in the underperformance of a network. For instance, you might want to use a cable that can endure extreme weather conditions or may require an easy-to-install indoor fiber optic cable to best suit your needs.

Well! That’s where Tight Tube and Loose Tube Fiber Optic Cables compete! Tight Tube cables allow for fast indoor connections, on the other hand, Loose Tube cables can endure outdoor facilities. Both have their advantages, choosing the wrong one could result in extra costs due to signal loss or undue installations. So, keep reading as we help you make the best decision by outlining the key differences between the two.

1) Basic Overview: Loose tube vs tight buffered Optical fiber

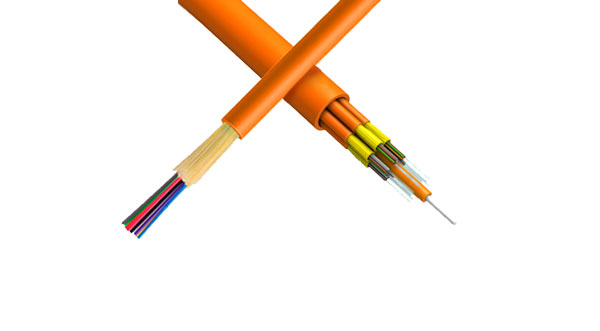

i) What is a Loose Tube Fiber Optic Cable?

“Loose Tube Fiber Optic Cables are a type of optical fibers that are enclosed within a protective hollow tube made of polyethylene (PE) or polybutylene terephthalate (PBT).”

Moreover, the optical fibers are not tightly bound within the tube. Rather, they are loosely bundled in the protective hollow tube so that they can shift within the spaces available. Thus, such a tube helps safeguard against harsh outdoor conditions such as moisture, abrupt changes in temperature, and even mechanical stress.

ii) What is a Tight Bufferd Fiber Optic Cable?

A Tight Tube Fiber Optic Cable is a type of fiber optic cable where each fiber is coated with a 900-micron thick protective buffer.”

You know the protective buffers are usually made of polymer materials like acrylate and PVC (polyvinyl chloride). This design or structure renders the cable quite strong and flexible while also allowing easy installation. This is especially true for indoor environments such as offices, hospitals, and data centers.

2) Key Differences Between Loose Tube and Tight Buffered Fiber Optic Cables

Let’s understand the differences between loose tubes and tight-tube optic fibers so that you can make the right choice for your needs. Let us analyze them in detail.

i) Environmental Resistance: Loose tube vs Tight buffer optical fiber

Loose Tube: This cable is designed for outdoor use. It is capable of withstanding heavy rainfall and snow due to the internal gel or powder acting as a water block to ensure the fibers are unharmed.

Moreover, they can resist extreme heat (70°C) and freezing temperatures (-40°C), because the loose structure allows the fiber to expand or contract freely with temperature changes. Apart from this, their outer jacket is made up of UV- UV-resistant PE which means sunlight is unable to damage it.

Tight Buffered: This cable is less suitable for outdoor use. Its preferred locations are in offices, homes, and data centers, provided that the temperature does not vary too much. It does not perform too well with water, so outdoor use requires additional protection.

- Outcome:

Thus, if you require a cable that can withstand extreme weather conditions, Loose Tube is the better choice. If you are working inside, Tight Buffered will be ideal.

ii) Strength and Flexibility: Tight buffer vs Loose tube optical fiber

Loose Tube: This tube is good against pulling and stretching, so it’s good for installation underground and aerial. The fibers inside, however, are fragile and require some form of safeguarding.

Tight Buffered: This type of cable is tough and quite protective. As we have discussed earlier coating is done directly to the fibers which means they cannot move on the inside. Thus, even if you bend, twist, and pull the cable, it will definitely not break, so it can be installed in tight spaces.

- Outcome:

In short, if you are looking for a cable that can undergo harsh outdoor conditions without damage, go for Loose Tube. If you want something that is easier to handle and bends more safely, go for Tight Buffered.

iii) Ease of Installation and Handling: Loose tube vs Tight buffer optical fiber

Loose Tube: The inside gel present in loose tube optical fiber makes it more complex to install, so extra time is spent on the installation. First, you must clean the gel off the fibers, which takes additional time, and then the connection can be made. Also, special tools are required to protect the fragile fibers during the installation process.

Tight Buffered: This type of cable is simpler and quicker to install or terminate. In addition, it does not require cleaning because there is no gel to remove. Thus, it can be connected directly to switches and routers without any additional procedures.

- Outcome:

Thus, I must say that use Tight Buffered if you are looking for a cable that is quick and easy to work with. However, if your needs are for larger outdoor projects, then put the time into learning about Loose Tube.

iv) Cost Considerations: Tight buffer vs Loose tube optical fiber

When it comes to the price of a fiber cable, it varies depending on the quantity needed as well as the application.

Loose Tube: For a new large area outdoor network, this cable is comparatively more efficient. This is due to its ability to contain 144 fibers in one bundle. This results in lower cable usage, which is more economical for materials and labor costs.

Tight Buffered: This cable is more expensive per meter due to the additional protective layer covering each fiber. However, it is cheaper for indoor purposes since it does not require additional components, such as gel and protective packaging tubes.

Moreover, a Quora user named Wayne Ruffner ( Telecom/network engineer ) has also shared his reviews regarding differences between loose tubes and tight buffered optical fiber.

v) Applications: Loose tube vs Tight buffer optical fiber

- Loose Tube Fiber Optic Cable Applications:

- Aerial fiber optic cabling between poles

- Municipal Area Networks (MANs)

- Highway and railway communications

- Military-grade industrial and defense environment.

- Underground and submarine fiber optics installations

- Telecommunications networks (internet services within a city)

- Urban fiber optic installations (Fiber to the Home FTTH) for residential blocks

- Tight Buffered Fiber Optic Cable Applications:

- CCTV security and alarm supervision

- School, office, and hospital networks

- Military-grade aerospace networks

- Local networks (LAN) and corporate networks

- Television and audio studios and radio stations

- Medical ultrasound, laser, and imaging devices

- Comparison table:

Loose Tube optical fiber | Tight-buffered optical fiber | |

| Weather Resistance | High (waterproof, UV-resistant, handles -40°C to 70°C) | Low (not water-resistant, best in stable environments) |

| Strength | Strong but delicate inside | Rugged and durable |

| Flexibility | Less flexible, harder to bend | Very flexible, easy to install |

| Ease of Installation | Harder (requires gel cleaning, special tools) | Easier (no gel, direct connection) |

| Fiber Capacity | Up to 144 fibers | Up to 24 fibers |

| Distance | Best for over 2 km | Best for under 2 km |

| Cost | Cheaper for large outdoor networks | Cheaper for indoor projects |

| Best For | Outdoor, long-distance | Indoor, short-distance |

3) Conclusion: Which Fiber Optic Cable is Right for You?

From all the above discussion, we have seen that there are advantages and disadvantages to both Loose Tube and Tight Tube Fiber Optic Cables. Now, it’s easy to select the cable that will best suit your requirements. Thus, choosing the right fiber cables aids in optimizing network performance, enhancing durability, and ensuring cost-effectiveness.

Moreover, you can contact Dekam Fibres to purchase high-quality fiber optic cables of different types best suited for outdoor and indoor uses.