Kabel gentian optik telah memajukan sistem komunikasi kita. Walau bagaimanapun, rahsia sebenar di sebalik sambungan yang lancar adalah bahan mereka. Sebagai contoh, kebanyakan gentian optik menggunakan helai kaca atau plastik nipis. Bahan-bahan ini jelas, kuat dan sukar untuk membolehkan penghantaran isyarat yang boleh dipercayai pada jarak jauh. Dalam artikel ini, kami akan membincangkan secara terperinci semua jenis bahan gentian optik. Jadi, teruskan membaca blog ini dan fahami bagaimana dunia kekal terhubung.

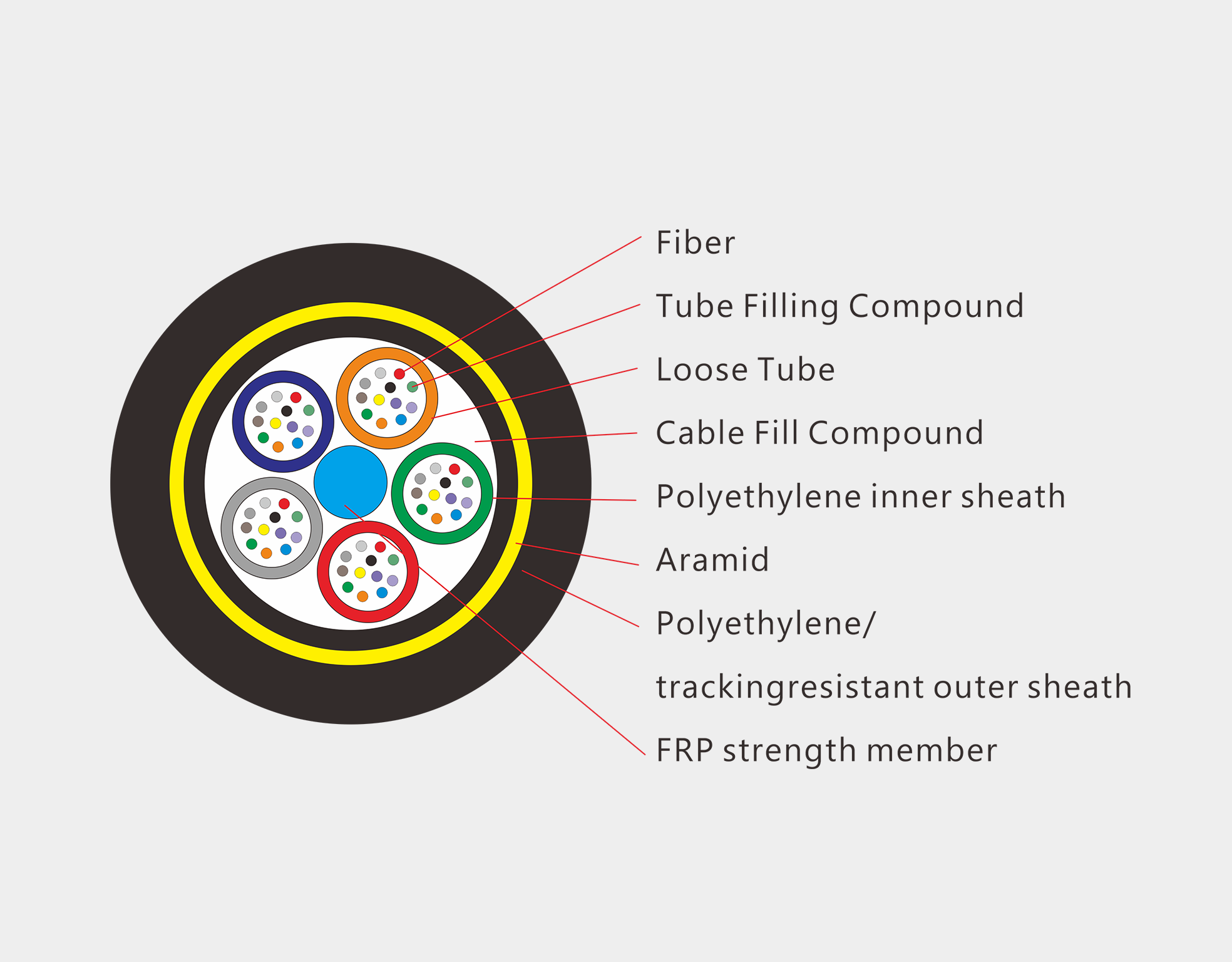

Rajah no 1 Bahan kabel optik api

1) Memahami bahan gentian optik

“Bahan gentian optik terdiri daripada polimer (plastik) atau kaca (silika) yang dibuat halus yang sangat lut sinar dan membenarkan cahaya melaluinya dengan kehilangan yang sangat sedikit”

- Ciri-ciri utama Bahan Gentian Optik

- Ketelusan Tinggi: Kaca (silika) dan plastik sangat lutsinar, yang membolehkan cahaya berlalu dengan sedikit kehilangan. Ini menghasilkan penghantaran data yang cekap pada jarak jauh.

- Ringan & Fleksibel: Gentian jauh lebih ringan daripada kabel tembaga. Lebih-lebih lagi, mereka lebih mudah dibengkokkan dan diputar tanpa pecah, memudahkan proses pemasangan. Oleh kerana berat dan fleksibilitinya yang ringan, gentian optik boleh menangani bintik-bintik sempit atau konfigurasi yang kompleks, menjadikannya penyelesaian praktikal untuk menjimatkan ruang.

- Ketahanan & Kekuatan Tinggi: Gentian optik mempunyai jangka hayat yang panjang kerana bahan yang kuat seperti Kevlar, salutan pelindung, dan lapisan kalis lembapan yang digunakan dalam pembinaannya. Kabel ini menahan cuaca, lenturan dan hentaman. Apabila dijaga dengan betul, ia boleh bertahan selama beberapa dekad dan kekal sebagai penyelesaian yang boleh dipercayai kerana jangka hayatnya.

- Tahan Panas & Api: Beberapa bahan yang digunakan untuk kabel gentian optik direka untuk bertolak ansur dengan haba dan juga kebakaran. Tidak seperti kabel logam, gentian optik tidak terlalu panas atau menghasilkan bunga api, yang menjadikannya lebih selamat untuk digunakan di bangunan, kilang atau kawasan berisiko tinggi yang lain.

2) Apakah Bahan Kabel Gentian Optik Diperbuat Daripada?

Bahan yang digunakan dalam kabel gentian optik biarkan cahaya melalui supaya maklumat boleh dihantar. Memandangkan setiap bahagian kabel gentian optik mempunyai fungsi individu, bahan mestilah teguh, telus dan tahan lama. Jadi, mari kita mendalami lebih mendalam!

i) Bahan Teras: Di Mana Cahaya Bergerak

Teras kabel gentian optik ialah bahagian telus pusat di mana cahaya bergerak. Ia perlu dibuat daripada bahan yang membenarkan cahaya bergerak melaluinya dengan kehilangan yang minimum.

- Kaca (gentian berasaskan silika): Kebanyakan kabel gentian optik menggunakan kaca yang sangat disucikan yang diperbuat daripada silika (SiO₂). Kaca ini sangat jelas, membolehkan cahaya dipancarkan pada jarak jauh tanpa kehilangan kekuatan. Internet pantas dan komunikasi jarak jauh memerlukan kaca.

- Plastik (Serat Optik Plastik, POF): Sesetengah kabel menggunakan plastik dan bukannya kaca. Gentian plastik ini lebih mudah digunakan secara ekonomi dan fleksibel, menjadikannya sesuai untuk jarak dekat seperti rangkaian rumah dan sistem kereta. Ini tidak akan berfungsi dengan rangkaian jarak jauh kerana plastik tidak menghantar cahaya dengan keamatan kaca.

Rajah no 2: Bahan yang manakah boleh digunakan untuk membuat helai gentian optik

ii) Bahan Pelapis: Memastikan Cahaya Di Dalam

Pelapisan adalah selongsong yang memegang teras. Ia menghalang cahaya daripada keluar dari gentian menggunakan pantulan dalaman total, yang memastikan cahaya disimpan di dalam teras.

- Kaca (pelapis berasaskan silika): Untuk kabel berprestasi tinggi, pelapisan kaca digunakan kerana ia mempunyai indeks biasan yang lebih rendah daripada teras. Ini meningkatkan kemudahan penghantaran cahaya.

- Kaca berdop fluorin: Menambah fluorin pada kaca khas mengurangkan indeks biasan, yang memastikan isyarat yang lebih jelas dengan meminimumkan kehilangan isyarat.

- Pelapisan berasaskan polimer: Digunakan dalam beberapa gentian optik plastik (POF), jenis ini menggunakan penutup plastik untuk meningkatkan fleksibiliti. Malangnya, ia membawa kepada peningkatan pengecilan isyarat, terutamanya dalam jarak jauh.

iii) Salutan dan Penampan: Perlindungan daripada Kerosakan

Oleh kerana diameter kabel yang dikurangkan, ia memerlukan lapisan pelindung untuk melindungi daripada calar, kelembapan dan lenturan.

- Salutan Polimer Akrilat: Sebilangan besar gentian optik dibalut dengan polimer ini untuk perlindungan tambahan terhadap kelembapan, habuk dan lenturan. Ini menghalang teras kaca atau plastik daripada pecah.

- Salutan Polimida: Kabel penutup ini di alam aeroangkasa dan mesin perindustrian, direka untuk menahan suhu yang melampau atau persekitaran yang mencabar.

iv) Bahan pengukuhan

Untuk melindungi gentian kaca halus daripada ketegangan, lenturan dan kerosakan luaran, bahan pengukuhan digunakan pada kabel gentian optik. Pilihan yang paling popular adalah seperti berikut;

- Kevlar ialah benang Aramid kerana beratnya yang ringan, fleksibiliti, dan ketahanannya terhadap regangan.

- Untuk situasi ketegangan tinggi, seperti kabel gentian optik udara dan kabel dasar selam, dawai keluli memberikan ketahanan tambahan.

- Anggota kekuatan dielektrik dan rod Gentian Kaca memberikan sokongan struktur sambil mengekalkan fleksibiliti.

Bahan-bahan ini memastikan bahawa kabel boleh mengendalikan keadaan cuaca yang teruk dan daya tarikan semasa pemasangan. Pemilihan bahan pengukuhan gentian optik yang betul ditentukan oleh aplikasi, sama ada di dalam, di luar rumah atau industri.

Selain itu, pengguna Qoura bernama Steve Blumenkranz, seorang jurutera mekanikal, juga telah berkongsi ulasannya mengenai bahan gentian optik. Beliau juga berkata bahawa kaca dopped dengan gemranium dioksida atau plastik adalah bahan yang biasa digunakan.

3) Bahan Jaket Kabel Gentian Optik

Jaket kabel gentian optik ialah lapisan paling luar yang mengelilingi dan melindungi kabel daripada pelbagai kerosakan. Ia mengekalkan komponen dalaman yang sensitif daripada kelembapan, haba, bahan kimia dan sebarang kesan fizikal.

Jaket gentian optik biasanya diperbuat daripada bahan plastik yang sangat tahan lasak yang tahan calar dan tahan lama. Antaranya, yang berikut adalah yang paling penting:

i) Polivinil Klorida (PVC): Polivinil Klorida ialah polimer sintetik yang diperbuat daripada monomer vinil klorida melalui proses pempolimeran. Bahan jaket jenis ini adalah kos efektif, fleksibel dan tahan api; PVC adalah pilihan yang paling popular. Ia pasti melindungi daripada kerosakan lembapan dan juga kerosakan fizikal kecil, yang sesuai untuk kabel dalaman seperti rangkaian pejabat atau sambungan internet rumah. Namun begitu, PVC tidak boleh digunakan dalam aplikasi yang memerlukan suhu tinggi kerana ia akan mengeluarkan asap toksik apabila dibakar.

Gambar no 3 Bahan jaket kabel gentian

ii) Polietilena (PE): PE ialah sejenis polimer termoplastik yang lebih ringan yang dihasilkan daripada monomer etilena. PE sesuai untuk kabel luar dan bawah tanah kerana ia tahan terhadap air, bahan kimia dan sinaran UV. Ia tidak mudah merosot dalam cuaca buruk, itulah sebabnya PE digunakan untuk kabel gentian optik di bawah jalan, di kawasan perindustrian dan juga di bawah lautan.

iii) Halogen Sifar Asap Rendah (LSZH): Tidak seperti PVC, plastik LSZH tidak membebaskan gas toksik semasa pembakaran, oleh itu menjadikannya sesuai untuk lokasi sensitif keselamatan seperti hospital, sekolah atau kawasan awam yang sesak.

iv) Elastomer Termoplastik (TPE) dan Poliuretana (PU): Bahan-bahan ini menunjukkan keanjalan dan daya tahan, membolehkan mereka digunakan untuk kabel yang kerap dibengkokkan, seperti yang digunakan dalam lengan robot dan kenderaan. PU melihat penggunaan dalam aplikasi perindustrian dan ketenteraan kerana rintangan minyak, kimia dan lelasan yang luar biasa.

5) Ucapan Penutup

Ringkasnya, pembangunan gentian optik mempamerkan inovasi yang dicapai dalam komunikasi moden yang berkelajuan tinggi dan jarak jauh. Walau bagaimanapun, ia hanya boleh dilakukan jika anda memilih bahan berkualiti tinggi, jika tidak, anda perlu menanggung kos penyelenggaraan dan pembaikan.

Jadi, jika anda ingin membeli kabel gentian optik berkualiti tinggi, maka Serat Dekam mempunyai penyelesaian yang paling optimum yang disesuaikan dengan keperluan anda. Jangan teragak-agak untuk melihat pilihan produk kami yang mengagumkan dan tingkatkan rangkaian anda hari ini!