In the world of fiber optic connectivity, few decisions are as fundamental — and as frequently misunderstood — as choosing between SC APC እና SC UPC connectors. These two variants of the ubiquitous SC (Subscriber Connector) dominate FTTH, data centers, CATV, and telecom networks worldwide, yet their differences in performance, application, and long-term reliability can make or break a deployment.

As of December 2025, with over 2 billion fiber connections active globally and PON technologies pushing toward 50G and 100G, understanding SC APC versus SC UPC is more critical than ever. This exhaustive guide covers every aspect: physical design, optical performance, real-world use cases, cost implications, compatibility issues, installation best practices, common myths, and future trends.

Written by Dekam Fiber — a leading manufacturer of pre-terminated cable, patch cords, and connectors serving operators in 80+ countries — this article is your ultimate reference for making the right choice in 2025 and beyond.

1. What Do SC, APC, and UPC Actually Mean?

1.1 SC Connector Basics

የ SC (Subscriber Connector or Standard Connector) was developed by NTT in the 1980s as a push-pull connector with a 2.5 mm ferrule. It quickly became the most widely used connector type due to:

- Simple push-pull coupling (no threading like FC)

- Low insertion loss

- High repeatability

- Duplex capability with clip

By 2025, SC remains the dominant connector in FTTH (especially drop cables and ONT terminations) and many enterprise applications.

1.2 UPC vs APC: The Endface Polish

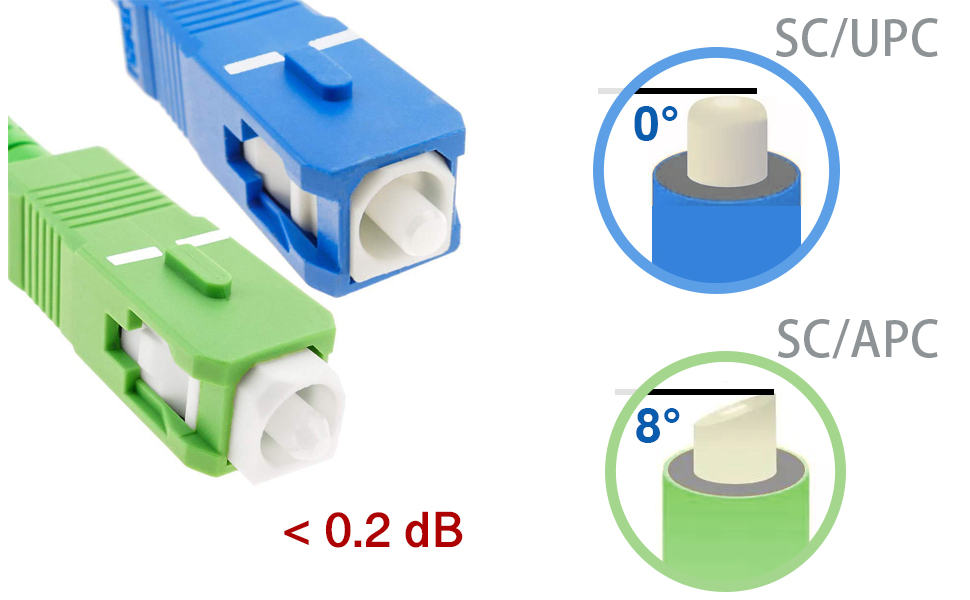

The key difference between SC UPC and SC APC lies in the ferrule endface polish:

- UPC (Ultra Physical Contact): Flat polish with a slight convex curve (radius ~10–25 mm). The fiber cores make direct physical contact.

- APC (Angled Physical Contact): 8-degree angled polish on the ferrule endface. Light reflections are directed away from the fiber core.

Both achieve “physical contact” (PC) to minimize air gaps, but the angle in APC dramatically reduces back-reflection.

| መለኪያ | SC UPC | SC APC |

|---|---|---|

| Endface Polish | Flat (slight convex) | 8° angled |

| Typical Return Loss | ≥50 dB | ≥60 dB (often ≥65 dB) |

| Typical Insertion Loss | 0.15–0.30 dB | 0.15–0.30 dB |

| Color Code (2025 std) | Blue housing | Green housing |

2. Optical Performance Deep Dive

2.1 Return Loss (Back-Reflection) — The Most Important Difference

Return loss measures how much light is reflected back toward the source.

- SC UPC: ~ –50 to –55 dB (0.001%–0.0003% reflection)

- SC APC: ~ –60 to –70 dB (0.0001%–0.00001% reflection)

In digital systems (Ethernet, GPON), –50 dB is usually acceptable. But in analog video (CATV, RFoG) or high-bit-rate systems (>10 Gbps), even small reflections cause:

- Signal interference

- Laser instability

- Bit error rate increase

- OSNR degradation in long-haul

Real-world example: In a 1550 nm CATV overlay on GPON, UPC connectors can cause visible tiling or noise, while APC eliminates it completely.

2.2 Insertion Loss

Virtually identical:

- Both ≤0.3 dB typical

- Premium assemblies ≤0.15 dB

The 8° angle in APC does not meaningfully increase insertion loss when properly manufactured.

2.3 Temperature and Environmental Stability

APC connectors maintain return loss better across temperature cycles (–40°C to +85°C) because the angled interface reduces micro-gaps from thermal expansion.

Independent testing (2024 Telcordia GR-326) shows APC assemblies retain ≥60 dB return loss after 500 cycles, while UPC can drop to –45 dB.

3. Visual Identification and Industry Standards

| ባህሪ | SC UPC | SC APC |

|---|---|---|

| Housing Color | ሰማያዊ | አረንጓዴ |

| Ferrule Endface | Flat, perpendicular | Clearly angled (visible under microscope) |

| Keying | None | Often notched key to prevent mating with UPC |

| Industry Standard | IEC 61754-4 | IEC 61754-4 (with angle) |

The green color and angled key are deliberate to prevent accidental UPC-APC mating, which causes ~10–15 dB return loss degradation.

4. Applications: Where Each Connector Wins in 2025

4.1 SC APC Dominates These Scenarios

- FTTH PON Networks (GPON, XGS-PON, 50G-PON): Reflection sensitivity in OLT receivers requires ≥60 dB return loss.

- CATV / RFoG Overlay: Analog video signals are extremely sensitive to reflections.

- Long-Haul and Metro DWDM: High OSNR requirements.

- High-Power Applications: Raman amplification, 1550 nm video.

- Any System Using Analog Modulation: SAT-IF, L-band satellite.

4.2 SC UPC Is Preferred Here

- Data Center Interconnects: Short-reach 10G–400G (SR, DR, FR, LR) where –50 dB is sufficient.

- Enterprise LAN: Multimode OM3/OM4/OM5 links.

- FTTx Active Ethernet (P2P): Less reflection-sensitive.

- Legacy Systems: Older equipment designed for UPC.

4.3 Hybrid Scenarios

Many operators use APC for outside plant (OSP) and UPC inside data centers, requiring careful transition planning.

5. Cost Comparison 2025 — Real Market Numbers

| Item | SC UPC (per connector) | SC APC (per connector) | Premium Difference |

|---|---|---|---|

| Bulk patch cord (3m, duplex) | $3.80–$5.50 | $4.20–$6.20 | 10–15% |

| Field-termination connector | $0.90–$1.40 | $1.20–$1.80 | 25–30% |

| Pre-terminated assembly | Baseline | +8–12% |

The premium for APC is modest and decreasing as manufacturing scale grows. The ROI from reduced troubleshooting and higher system margin often pays back in months.

6. Compatibility and Mating Risks

Never mate UPC with APC:

- Physical contact is poor due to angle mismatch

- Return loss drops to ~ –35 to –45 dB

- Can damage ferrules

Modern APC connectors include a notched key to physically prevent mating with UPC.

7. Installation and Termination Best Practices

7.1 Field Termination Differences

- UPC: Easier to polish flat

- APC: Requires precise 8° angle control — more challenging in field

Recommendation: Use factory pre-terminated APC assemblies for OSP; field-terminate UPC for indoor/data center.

7.2 Cleaning and Inspection

Both require meticulous cleaning, but APC’s angled face makes contamination more visible under inspection scope.

Best practice: Always use IEC 61300-3-35 compliant inspection and cleaning.

8. Performance in Emerging Technologies (2025–2030)

| ቴክኖሎጂ | Preferred Connector | Reason |

|---|---|---|

| 50G-PON / 100G-PON | APC | Higher reflection sensitivity at higher rates |

| Coherent DCI (400G/800G ZR) | UPC or APC (depends on vendor) | Coherent detection tolerates reflection better |

| Analog RF Video | APC only | No alternative |

| Multimode 400G SR8 | UPC (PC polish) | Standard for MMF |

9. Common Myths and Misconceptions Debunked

Myth 1: “APC has higher insertion loss”

Reality: No measurable difference when properly manufactured.

Myth 2: “UPC is fine for FTTH”

Reality: Causes intermittent issues in millions of deployments; major operators mandate APC.

Myth 3: “You can’t mix UPC and APC in the same network”

Reality: You can, but only with proper isolation (e.g., UPC in data center, APC in OSP).

Myth 4: “APC is much more expensive”

Reality: 10–15% premium, offset by lower maintenance.

10. Dekam Fiber’s 2025 Product Recommendation

| Your Application | Recommended Connector |

|---|---|

| FTTH drop cables, ONT connections | SC APC (green) |

| Data center single-mode links | SC UPC (blue) |

| CATV / RF overlay | SC APC only |

| Mixed environment | Hybrid assemblies with clear labeling |

We manufacture both with ≤0.15 dB insertion loss and ≥65 dB return loss (APC).

Conclusion: The Clear Winner in Most Modern Networks

In 2025, SC APC is the superior choice for the vast majority of new deployments — especially any PON-based FTTH, CATV, or high-bit-rate system.

The modest cost premium is overwhelmingly justified by:

- 10–20 dB better return loss

- Dramatically reduced reflection-induced errors

- Higher system margin for future upgrades

- Proven reliability in billions of connections

SC UPC still has its place in short-reach data center and multimode applications, but for anything involving outside plant or analog signals, APC is non-negotiable.

Don’t risk your network’s performance on outdated assumptions. Choose the right connector from day one.

Dekam Fiber offers the industry’s widest range of SC APC and SC UPC assemblies — factory-terminated, 100% tested, with lifetime traceability.

Need help deciding for your specific project?

Contact us for a free consultation and sample kit.