In the ever-expanding universe of fiber optic networks, where speeds reach 800G and beyond while global FTTH connections surpass 2.2 billion by late 2025, one cable design continues to dominate aerial installations: the figure 8 fiber optic cable.

Commonly referred to as figure 8 cable, figure 8 fiber cable, figure 8 aerial cable, self-supporting figure 8 cable, or simply figure 8 optical cable, this ingenious structure combines optical fibers with an integrated messenger wire in a distinctive “8” cross-section. This self-supporting design has revolutionized overhead fiber deployment, making it faster, cheaper, and more reliable than traditional lashed or ADSS alternatives.

As of 2025, figure 8 fiber optic cable remains the preferred choice for rural broadband, urban pole-to-home drops, 5G small cell backhaul, and utility co-deployment projects worldwide. Its ability to span hundreds of meters without additional support hardware has made it indispensable in bridging digital divides.

This extended guide dives deep into every facet of figure 8 fiber optic cable: its history and evolution, detailed construction, technical specifications, mechanical properties, advantages and limitations, real-world applications, installation methodologies, comparisons with competing technologies, 2025 innovations, procurement strategies, cost analysis, common pitfalls, and future outlook.

Whether you are a telecom operator planning massive aerial rollouts, a contractor managing field installations, a network designer evaluating cable options, or a procurement professional sourcing materials, this article — produced by Dekam Fiber, a premier manufacturer of figure 8 fiber cable solutions — will serve as your authoritative resource.

1. The Origins and Evolution of Figure 8 Fiber Optic Cable

The concept of self-supporting aerial cable dates back to the early days of telecommunications when copper pairs were suspended between poles using integrated steel messengers. The transition to optical fiber in the 1980s–1990s required new thinking, as glass fibers are far more fragile than copper.

Early aerial fiber solutions involved lashing standard loose-tube cables to a separate steel messenger wire — a labor-intensive process prone to wind-induced vibration and ice loading failures.

The breakthrough came in the mid-1990s when manufacturers developed the figure 8 fiber optic cable design: extruding the fiber-containing cable directly onto a messenger wire with a connecting web, creating the iconic “8” shape. This eliminated lashing entirely while providing excellent mechanical protection.

Key Milestones

- 1995–2000: Initial deployments in North America and Europe for rural telephony.

- 2005–2010: Widespread adoption during early FTTH builds; introduction of all-dielectric versions using FRP messengers.

- 2011–2015: Standardization of G.657 bend-insensitive fibers in figure 8 drop cable for easier installation.

- 2016–2020: Explosion in use driven by government broadband initiatives (e.g., U.S. CAF, EU Digital Agenda).

- 2021–2025: Integration of micro-cables, higher fiber counts (up to 432), enhanced ice/wind loading ratings, and sustainable materials.

By late 2025, figure 8 cable accounts for over 60% of new aerial fiber installations globally, particularly in cost-sensitive and rapid-deployment scenarios.

2. Detailed Construction of Figure 8 Fiber Optic Cable

The genius of figure 8 fiber cable lies in its integrated design.

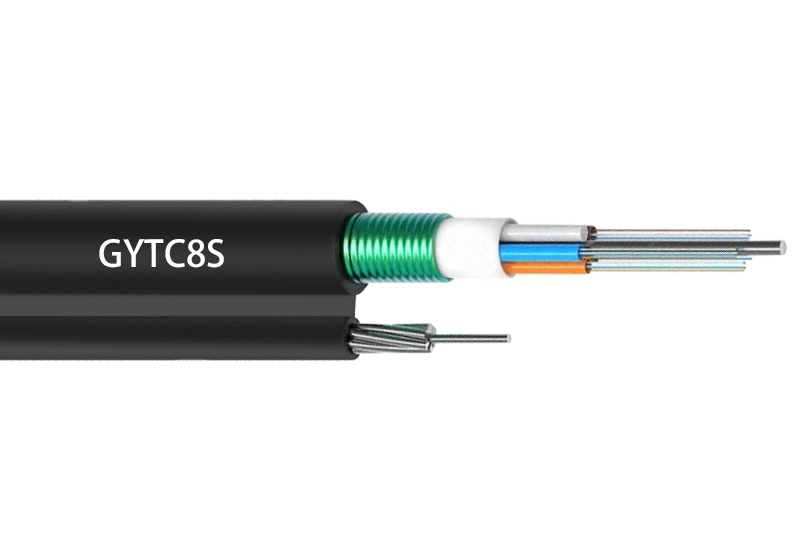

2.1 Upper Section: The Messenger

- 材料: Galvanized steel wire (1.0–4.0 mm diameter) or FRP rod (for all-dielectric)

- Function: Bears all tensile load during spanning and ice/wind events

- 力量: Rated 3000–15000 N ultimate tensile strength

2.2 Connecting Web

- Thin PE extrusion linking messenger to fiber section

- Designed to tear cleanly for separation during termination

2.3 Lower Section: Optical Unit

- Central Strength Member: FRP rod

- Loose Tubes: PBT with thixotropic gel; each tube holds 6–12 fibers

- Water-Blocking: Dry yarn/tape or gel-filled

- Rip Cords: For easy sheath removal

- 外護套: UV-stabilized black MDPE/HDPE

2.4 Variations and Special Designs

- All-Dielectric Figure 8 Cable: No metal — safe near power lines

- Armored Figure 8 Fiber Cable: Corrugated steel tape for rodent/direct contact protection

- Flat Figure 8 Drop Cable: 1–12 fibers for last-mile FTTH

- Micro Figure 8 Cable: 3–6 mm total diameter for urban aesthetics

- Hybrid Figure 8: Integrated copper pairs for power delivery

Dekam Fiber’s 2025 portfolio includes over 50 figure 8 fiber optic cable variants optimized for every environment.

3. Mechanical and Environmental Performance

Figure 8 cable must withstand decades of exposure.

3.1 Tensile Strength and Sag

- Steel messenger versions: up to 15000 N

- Typical sag tables allow 300–500 m spans at NESC heavy loading

3.2 Wind and Ice Loading

- Rated for 25–50 mm radial ice

- Wind speeds up to 140 km/h with vibration dampers

3.3 Temperature Performance

- Operating: –40°C to +70°C

- Installation: –20°C to +50°C

3.4 UV and Chemical Resistance

- 25+ year black PE sheath

- Resistant to oils, acids, and agricultural chemicals

Independent testing confirms figure 8 aerial cable survives 20+ years in harsh conditions.

4. Advantages of Figure 8 Fiber Optic Cable

| Advantage | Detailed Benefit |

|---|---|

| 自支撐設計 | Eliminates separate messenger wire and lashing hardware |

| Reduced Installation Cost | 30–50% lower labor vs lashed cable; single-step deployment |

| Lower Pole Loading | One cable instead of two — critical for utility negotiations |

| Faster Deployment | Crews can install 2–3× more distance per day |

| Easy Maintenance and Identification | Distinctive shape simplifies troubleshooting |

| Excellent Mechanical Protection | Messenger absorbs tension; web protects fiber section |

| Versatile Mounting Options | Compatible with standard suspension and dead-end hardware |

Figure 8 fiber cable consistently delivers the best cost-per-kilometer in aerial applications.

5. Limitations and When to Choose Alternatives

While excellent, figure 8 cable has constraints:

- Maximum span limited by messenger strength (vs ADSS which can exceed 1000 m)

- Steel versions conduct lightning (use all-dielectric in high-risk areas)

- Not suitable for duct or direct-buried (use standard loose-tube)

Alternatives:

- ADSS for very long spans or high-voltage areas

- Lashed cable where existing messenger exists

- Duct cable for underground

6. Applications of Figure 8 Fiber Optic Cable Worldwide

6.1 FTTH and FTTx Last-Mile

The dominant use: figure 8 drop cable from distribution point to home.

6.2 Rural and Suburban Broadband

Long-span figure 8 aerial cable connecting remote communities.

6.3 5G and Small Cell Networks

Compact figure 8 fiber cable feeding urban small cells.

6.4 Utility and Power Line Co-Deployment

All-dielectric versions alongside MV/HV lines.

6.5 Temporary and Emergency Networks

Rapid aerial deployment for disasters or events.

6.6 Campus and Industrial Parks

Overhead connections between buildings.

7. Installation Best Practices for Figure 8 Cable

7.1 Pre-Installation Planning

- Perform sag/tension calculations (software like SAG10 or PLSCADD)

- Verify pole loading capacity

- Plan hardware: suspension clamps, dead-ends, vibration dampers

7.2 Deployment Techniques

- Use dedicated figure 8 cable payout reels with braking

- Maintain minimum bend radius (20× cable diameter)

- Install in “figure 8” payout pattern to remove torsion

- Attach messenger first, then secure fiber section

- Leave adequate service loops

7.3 Safety Considerations

- Proper PPE and pole climbing certification

- Grounding of steel messenger

- Weather restrictions (no installation in high wind or ice)

Dekam Fiber provides detailed installation guides and training videos with every order.

8. Comparison with Competing Aerial Technologies

| 科技 | 自給自足 | Max Span | 成本 | Installation Complexity |

|---|---|---|---|---|

| Figure 8 Cable | 是的 | 500 m | 低的 | Simple |

| ADSS | 是的 | 1500 m | 高的 | Complex |

| Lashed Loose-Tube | 不 | 500 m | 中等的 | Labor-intensive |

| 光纖複合架空地線 | 是的 | 500 m | 非常高 | Very Complex |

Figure 8 fiber optic cable consistently wins on total cost of ownership for spans under 500 m.

9. Innovations in Figure 8 Fiber Optic Cable for 2026–2030

9.1 Higher Fiber Counts

288–432 fiber figure 8 cable using micro-tubes and ribbon.

9.2 Enhanced Environmental Ratings

- 50 mm ice load

- 200 km/h wind survival

9.3 Smart Figure 8 Cable

Integrated sensors for strain/temperature monitoring.

9.4 Sustainable Manufacturing

70–100% recycled PE sheath.

9.5 Hybrid Designs

Combined fiber + low-voltage power delivery.

Dekam Fiber’s Eco Series figure 8 fiber cable uses 80% recycled materials while maintaining full performance.

10. Procurement Guide and Cost Analysis 2025

| 光纖數量 | Price Range USD/m | Typical Drum Length |

|---|---|---|

| 12F | 0.42–0.62 | 4–6 km |

| 48F | 0.78–1.15 | 4 km |

| 96F | 1.10–1.60 | 4 km |

| 144F | 1.45–2.05 | 2–4 km |

| 288F | 2.20–3.10 | 2 km |

Buy factory-direct for 25–40% savings vs distributors.

11. Common Issues and Troubleshooting

- Messenger corrosion (use galvanized or all-dielectric)

- Web tearing during installation (proper technique)

- Excessive sag (correct tensioning)

- Bird damage (spiral wraps in problem areas)

Conclusion: The Enduring Relevance of Figure 8 Cable

More than 30 years after its introduction, figure 8 fiber optic cable remains the smartest, most economical choice for the majority of aerial fiber deployments.

Its perfect balance of strength, simplicity, and cost-effectiveness ensures it will continue dominating overhead installations through 2030 and beyond.

Dekam Fiber manufactures one of the world’s most comprehensive figure 8 fiber cable ranges — from 2-fiber drop to 432-fiber feeder — all with industry-leading quality, 10-year warranty, and global delivery.

Ready to specify figure 8 cable for your next project?

Contact Dekam Fiber today for engineering support, samples, or competitive pricing.

The most reliable aerial networks start with the classic figure 8 fiber optic cable.